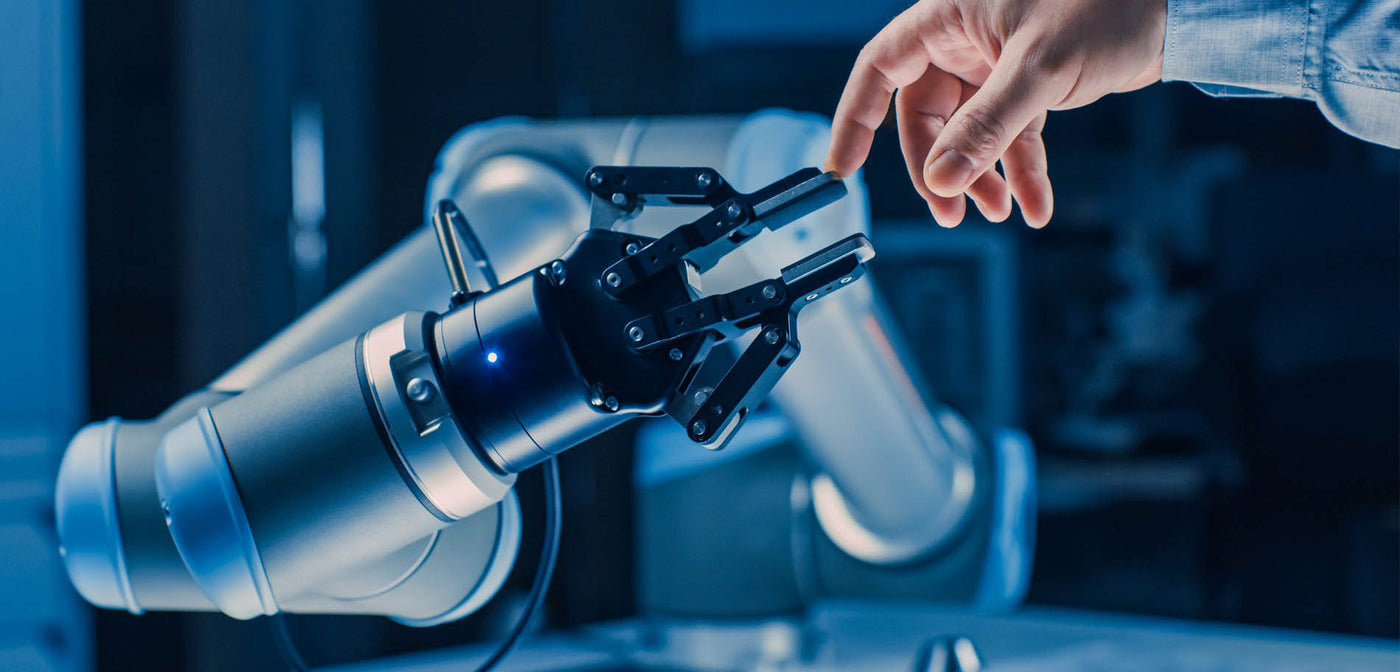

UNDERSTANDING COBOTS

Cobots are designed to work alongside humans, providing assistance and enhancing productivity in various industries. Here are a few reasons why cobots can cope well with the tasks such as:

- Machine tending

- Carton erecting

- Surface finishing

- Pick and place

- Assembly Inspection

- Welding

- Dispensing

And they will copycat program too! Here are 7 other interesting outcomes such as:

1. Improved Workplace Safety:Cobots are equipped with advanced sensors and safety features that allow them to work safely in close proximity to humans. They can detect and react to any unexpected contact, minimising the risk of injuries. That includes light and temperature as well as fragility!

2. Flexibility: Cobots are highly flexible and can be easily programmed and reprogrammed to perform different tasks. This makes them adaptable to changing production needs and allows for efficient multitasking and almost no downtime.

3. Ease of Use: Cobots are designed to be user-friendly, with intuitive programming interfaces that do not require extensive technical expertise. This enables operators to quickly set up and operate cobots, reducing downtime and increasing productivity, easily is measured in minutes of arrival!

4. Accuracy and Consistency: Cobots are known for their precise and repeatable movements. They can consistently perform tasks with high accuracy, reducing errors and increasing overall quality in industries such as inspection, assembly, and welding. With camera technology an other affordable Ai accountability is instantly achieved with highly accurate audit trails. What that means is detectable materials control in processing and production.

5. Increased Efficiency: By automating repetitive and physically demanding tasks, cobots can help improve efficiency and productivity. They can work tirelessly without fatigue, leading to faster cycle times and increased throughput. They don’t need comfort breaks either.

6. Collaborative Nature: Cobots are designed to work alongside humans, collaborating and sharing workspace. They can assist with tasks that require human dexterity, problem-solving, and decision-making, enhancing human skills rather than replacing them, they don’t require drug and alcohol tests either.

7. Cost-Effectiveness: Cobots can offer a cost-effective automation solution compared to traditional industrial robots. They have a smaller footprint, require less infrastructure, and can be easily redeployed for different tasks, making them a more affordable option for small and medium-sized businesses. Especially small businesses

HOW CAN COBOTICS ASSIST WITH PRODUCTION?

While Robots can handle extremely heavy or complex tasks, their little cousins excel in providing efficient and safe assistance in a wide range of industries, making them a valuable tool for enhancing productivity and collaboration in the workplace.

Here are a selection of industries that use cobotics:

WHAT ARE THE COSTS INVOLVED?

The payback period for cobots can vary depending on various factors, including the specific application, industry, and the level of automation it provides. Here are 5 factors to consider when estimating the payback period:

1. Labour Cost Savings: Cobots can help reduce labour costs by automating repetitive tasks, thereby freeing up human workers for more skilled and value-added activities. The payback period can be shorter if the labour cost savings are significant.

2. Increased Productivity: Cobots can enhance productivity by working continuously without breaks, reducing cycle times, and minimizing errors. They don’t smoke either, unless something is seriously wrong. The payback period can be influenced by the extent of productivity gains achieved through cobot implementation.

3. Reduced Downtime: Cobots can help reduce downtime by ensuring consistent and reliable enhanceable production. Any decrease in production interruptions can contribute to a shorter payback period.

4. Quality Improvement: Cobots can improve product quality and reduce defects through their precise and consistent movements, they don’t have “senior moments” lapses of concentration or arguments. Inevitably there are costs avoided that result in associated rework or product recalls.

5. Scalability and Flexibility: The ability of cobots to be easily reprogrammed and redeployed for different tasks without demanding pay increases improve their appeal and value and shortening the payback period. They can adapt to changing production needs and support future growth.

Although payback period can vary widely depending on the specific circumstances and industry. In some cases, payback within a year or two, while in others, it may take several years to realise& the return on investment. Three shifts is a no brainer.

Some examples assuming cobot costs of say £100,000 where the company estimates that it can save £40,000 per year in labor costs by automating the task are a fairly obvious calculation, but if you lease it the savings start day one and by month 4 it’s in the P&L account visibily.

WAREHOUSE COBOTICS

Warehousecoboticsrefers to the use of collaborative robots, or cobots, in warehouse operations. These cobots work alongside human workers to perform various tasks, such as picking and packing items, transporting goods, and organizing inventory. They are designed to assist humans rather than replace them, with the goal of increasing efficiency, productivity, and safety in the warehouse. Cobots are programmed to work in harmony with humans, except you can also easily program and adapt them using simple almost copycat programming, often using sensors and advanced technology to ensure safe and seamless collaboration. Overall, warehousecoboticscombines the strengths of humans and robots to optimise warehouse operations.

Need a Quote?

Get in-touch with your exact requirements